STANDARDS ARE STANDARD FOR US

Global standards enable seamless traceability

As a wholly owned subsidiary of GS1 Germany, fTRACE uses the latest global standards of the GS1 system. This enables companies, sites, items or transport units to be identified globally with a unique ID. The most well-known GS1 standard is the GTIN (formerly EAN), which is used for identifying merchandise. The use of GS1 standards is the foundation for enabling seamless and efficient traceability of products along the entire supply chain.

The advantages of standardised data

Unambiguous data

The traceability solution fTRACE is based on the GS1 standard EPCIS. In other words, the relevant process steps in the supply chain are summarised in terms of events. These events enable users to understand which process steps took place when and where, and which products were involved. Moreover, users can access this data whenever they need to. fTRACE also uses the global GS1 standards GLN and GTIN to ensure the nested identification of companies and products.

Decentralised data entry

Every stakeholder enters event data for their own process steps. The individual events will then be combined to form a complete supply chain. In this way, fTRACE plays a key role in preventing data manipulation.

Structured, interoperable data

By using an agreed, uniform data format, traceability data can be shared all the way along the supply chain in a standardised, structured manner. This is a prerequisite for the efficient processing and usage of data, and enables it to be transferred to other standardised traceability systems.

Data models for flexible use

The GS1 standard EPCIS can be implemented flexibly, regardless of the sector. Although the food industry is the main focus of fTRACE today, it can also be used to trace other products, such as packaging materials, cosmetics and pharmaceuticals. It is simply a matter of taking the sector’s key processes into account, together with any legal requirements.

Secure data

fTRACE data is encrypted and stored in a cloud located in Germany. This not only guarantees good system performance, but also ensures that the traceability solution corresponds to customer needs in terms of security. The system is also ISMS-certified, testimony to its compliance with the requirements of an information security management system as defined by ISO/IEC 27001. The annual inspection is carried out by TÜV Süd.

Data access controlled by user rights

The data transferred to fTRACE remains the possession of the actual data owner at all times. You can determine who is allowed to see and use the data – for example, the direct recipient of the goods, all companies in the upstream chain or just a single, specified company. Access to data is always attribute-based. This means that data relating to volume can be restricted exclusively to the direct recipient of the goods, for example.

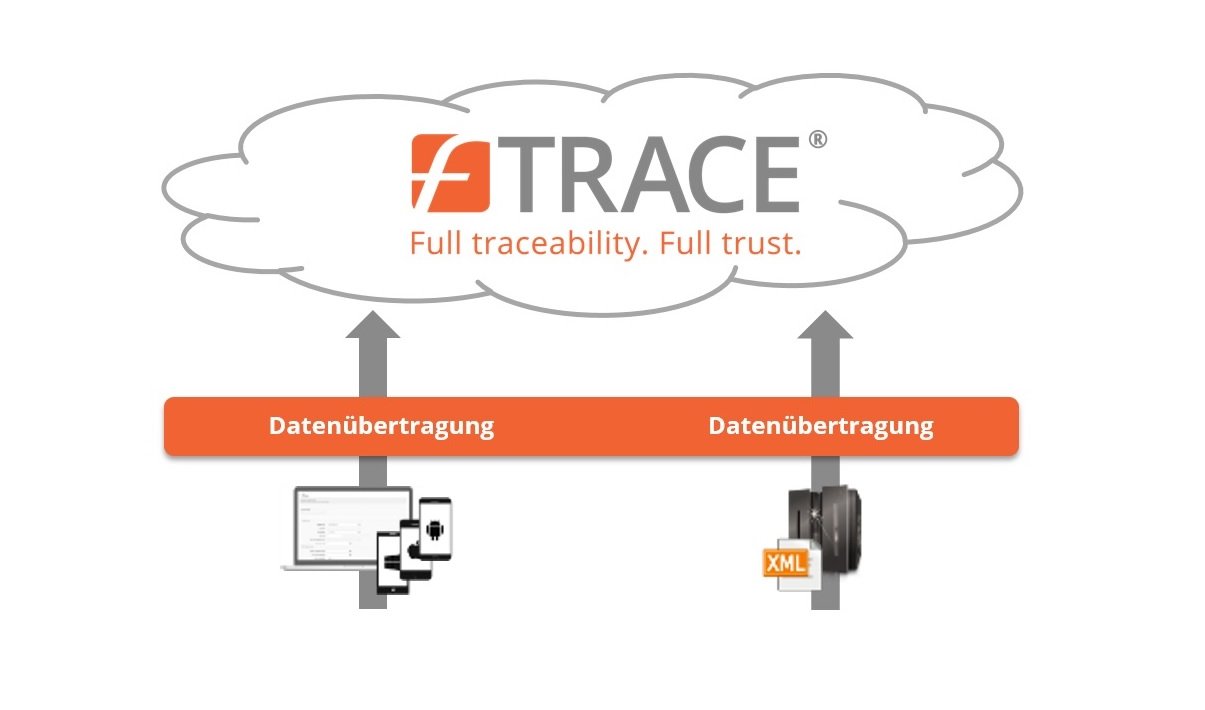

How can data be transferred and retrieved?

fTRACE offers a range of ways in which data can be transferred and retrieved. As a general rule, there are two different approaches, depending on the size of the company and the level of technical maturity of its IT infrastructure:

- Smaller companies with a low volume of data can input their data manually onto a website, where there data will be displayed.

- Medium-sized and larger companies can use interfaces to transfer and download data automatically; they can also connect fTRACE directly with their own ERP system.

Experienced fTRACE personnel provide companies with technical support to connect the two systems. Their objective is to enable companies to transmit perfect quality traceability data to fTRACE on an ongoing basis.

Further informationen

What data can be recorded?

Traceability data can be split into a myriad of different levels and can be classified into three distinct types of data. This includes master data about companies and products, dynamic batch data and data extensions that can be generated from batch data.

Master data

Master data about companies and products is static information. This data is stored clearly in fTRACE behind the unique global GS1 identifiers – the GLN (Global Location Number) and the GTIN (Global Trade Item Number). Shipping units can also be rendered traceable by using the SSCC (serial shipment container code); likewise, transport containers can be labelled with a GIAI (Global Individual Asset Identifier) and a GRAI (Global Returnable Asset Identifier). Master data can also include certificates relating to the company or products.

Variable data

Based on the master data, event-related data can also be inputted into fTRACE – using the global GS1 standard EPCIS (Electronic Product Code Information Services). The data format prescribed by EPCIS provides answers to four questions relating to every event in the supply chain: what took what place when, where, and why? EPCIS enables any type of supply chain to be pieced together flexibly like building blocks.

Data extensions

Once a supply chain has been defined using master data and events, data extensions such as sensor data, laboratory values, transaction data and other data relevant to the downstream supply chain can be attached. For example, temperature data can be attached to events to ensure the seamless monitoring of cold chain temperatures.